- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

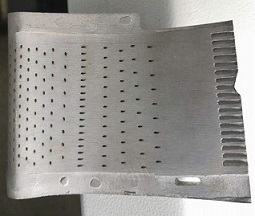

Latest 6 axis CNC Drilling EDM machine

I. Main Parameters of Latest 6 axis CNC drilling EDM machine

|

Model |

TD430N |

|

Worktable size |

φ200mm |

|

Table travel(X×Y*Z) |

400×300*400mm |

|

W axis travel |

400 mm |

|

B axis rotation Angle |

±110° |

|

C axis rotation Angle |

0-360° |

|

C axis rotation table load |

20kg |

|

Max distance between worktable to electrode chuck |

400mm |

|

Max workpiece dimension |

φ200×250mm |

|

Electrode diameter |

0.3-3.0 mm |

|

Best roughness |

1.6um |

|

Recast layer thickness |

0.02mm |

|

Input/output interface |

USB 、LAN、RS-232 |

|

Control type |

Industrial computer |

|

Screen |

15″LCD touch-screen |

|

Programming software |

UG, CAD |

|

Pitch compensation |

Yes |

|

X/Y/Z Positioning accuracy |

0.010mm |

|

X/Y/Z Repeated positioning accuracy |

0.006mm |

|

B/C axis positioning accuracy |

15″ |

|

B/C axis repeated positioning accuracy |

10″ |

|

Type of working fluid |

Deionized water |

|

Max. working current |

30 A |

|

Max. drilling speed |

30-60mm3/min |

|

Machine dimension |

2300×2100×2500 mm |

II. The machine characteristics:

1. It is mainly used for drilling small holes in complex spatial positions of aerospace engine rings and blade parts.

2. It can drill various hardened materials such as high-temperature alloys, titanium alloys, stainless steel, hard alloys, quenched steel, etc.

3. Its advantages are higher drilling speed, higher accuracy, better surface quality, and larger depth to diameter ratio.

4. It has the function of automatic replacement of electrodes and guides.

5. It has the function of automatic programming of UG model spatial hole positions.

6. It has functions of automatically changing the drilling hole position, automatically trimming the electrode, automatically detecting the machining zero position, automatically changing the gauge, automatically controlling the machining depth, and automatically sending a message when the electrode is used up, selecting any single hole for machining. The programming for sample hole position collection can be trained here.

7. It has the function of automatic controlling and processing of the working fluid conductivity.

8. It can use the simple electrodes to mill the waist shaped holes.

9. It supports the establishment of connected automatic production lines, which can achieve higher productivity and automation levels.

10. It can be equipped with a contact probe, supporting automatic alignment, detection and positioning, and automated production.

11. Various models of machine tools can be customized according to the users’ special requirements.

III. Advantages of the machine

1. It is composed of main engine, CNC pulse power control cabinet, deionized water treatment system, etc.

2. Main machine: composed of bed, column, X axis, Y axis, Z axis, W axis, B axis, C axis.

3. CNC pulse power control cabinet: It is composed of industrial control computer, CNC system, touch screen, servo motors drive, machine tool electrical appliances, high-efficiency discharge pulse power supply, rocker arm waterproof and antipollution stainless steel keyboard control table, multi-function remote control hand box, etc.

4. Deionized water treatment systems: the 400 L stainless steel water tank, filter system, to ion system, conductivity detection system, high pressure water pump, etc.

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap