- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

Electrical Discharge Saw(EDS) Used for ESR Ingots Cutting at a Super Fast Speed.

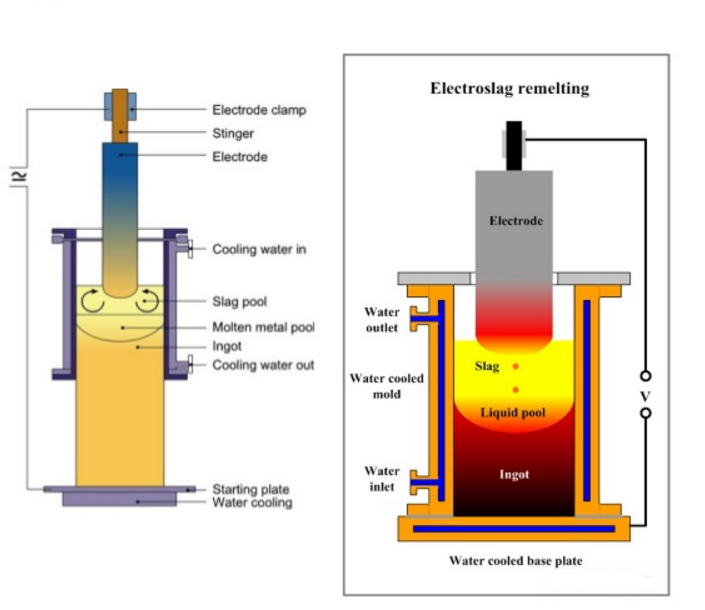

Electroslag remelting (ESR), is also known as electro-flux remelting, is a process of remelting and refining steel and other alloys for mission-critical applications in aircraft, thermal power stations, nuclear power plants, military technology, etc. And the refining steel and other super alloys are too hard to be cut with normal band saw cutting off machine.

How to cut these hardened material bars, especially the larger diameter bars? To solve this problem, we have developed a new electrical discharge sawing machine(EDS). The EDS machine can be used to cut these super hardened material at a fast cutting speed: 1800 square mm per min( on the cut off cross section).

Job of EDS machine

ESR ingots

One new Electrical discharge sawing machine is installed successfully in our client’s workshop in India in October of 2018. And it is used to replace the band saw machines for cutting the refining ESR ingots. Here is one of the cutting test results at our client’s place as following:

1. Job: electroslag refining special steel of dia540mm.

2. Cutting off time: 117minutes.

3. Speed: 1950 sq mm/min.

Attached please find some pictures of the EDS machine in our client's workshop for your reference.

New EDS machine installed in Indian client's workshop

If you are special steel makers and have a lot of larger ESR steel bars or to cut, the electrical discharge sawing machine is the best cutting machine tool for you.

For anything we can do to support you on electrical discharge sawing (EDS) machines, please feel free to contact us.

Tech EDM Team.

sale@techedm.com

www.techedm.com

- What is Medium Speed Wire Cut EDM?

- How to select the electrode tubes for your small hole EDM machines?

- Our coiled brass tube is very popular for its fine quality in overseas market

- TECH EDM brand EDM parts are popular in Germany

- How to avoid the pitting start line during Wire cutting EDM?

- How to improve the cutting speed for the wire EDM machine?

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2018-10-23

2018-10-23