- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

EDS’ Advantages Comparing to WEDM

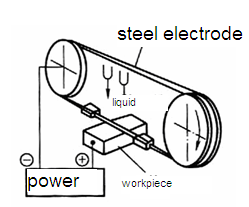

The electronic discharge sawing (EDS) is a new metal cutting process, applying spark erosion – the basic operating principle of wire EDM – with a rotating mild steel belt to promise less material waste, less environmental impact, greater productivity and low operating costs. This new technology could change the future of cutting hard, exotic and composite metals.

In EDS, a mild steel belt is stretched across an automatic tensioning system. The only reason mild steel is used for the blade, instead of some other material, is that mild steel is very accessible and really inexpensive to use. Theoretically, any electrically-conductive material blade will work. As the rotating band is lowered onto the workpiece, sodium silicate dielectric is sprayed across the band and the spark-erosion process begins, cutting at an average of 1500 mm2/ minute.

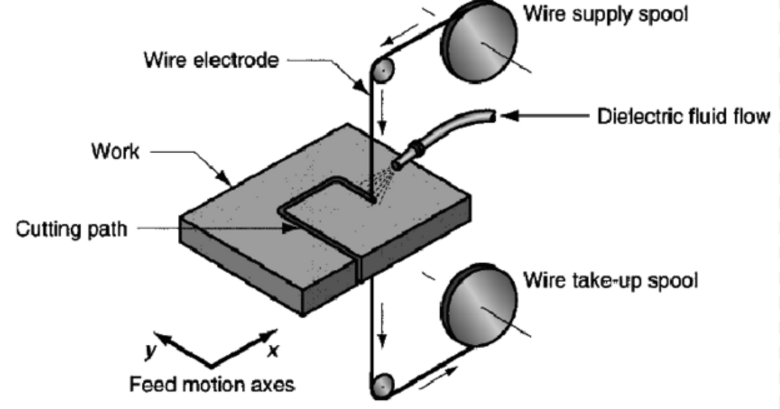

Comparing with WEDM (wire EDM), EDS machine has the following advantages:

|

1. EDS can cut any conductive metal, esp for hard, exotic and composite metals |

|

2. EDS has a higher cutting speed: Max:1800mm2/min |

|

3. EDS has a lower cutting tool cost (the electrode is cheaper: 1.2USD/pcs) |

|

4. EDS can save material cost (the cutting gap is smaller: 1.5-2mm) |

Here is the detailed comparison between EDS and wire EDM as following:

|

Comparison between EDS and WEDM |

||

|

Machines |

EDS |

WEDM |

|

Full Name |

Electronic discharge sawing |

Wire electronic discharge machining |

|

Job material |

Any conductive metal, irrespective of hardness,esp for hard, exotic and composite metals |

|

|

Cutting tools |

Mild steel electrode |

Brass/Molybdenum wire |

|

Coolant |

sodium silicate dielectric |

resin dielectric |

|

Cutting current |

High |

Low |

|

Cutting speed(mm2/min) |

1500-1800 |

100-300 |

|

Cutting gap(mm) |

0.15-0.35 |

1.5-2.5 |

|

Cutting surface |

Normal |

Good finish |

|

Accuracy |

Commen |

High accuracy |

|

Cutting shape |

Straight line |

Complex |

|

Operation cost |

Very Low |

Higher |

|

Application areas |

Large size raw material ingots or blanks,aerospace, defense, nuclear and solar energy, medical devices, etc |

Extrusion dies, wire drawing dies and other similar mold making |

EDS theory Picture:

Wire EDM theory Picture:

For anything we can do to support you on EDS or EDM machines, please feel free to contact us.

Have a Nice day.

Tech EDM Team

- EDM items on Die & Mould of China 2016

- The Reasons and Solutions of the Bad Roughness During the Finish Cutting

- Customer's feedback about our product quality

- Look, a client's feedback about our small hole drilling EDM machine

- How to improve the cutting efficiency of your wire EDM machine?

- Wire EDM consumable part EDM Resin shipped to overseas market again

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2022-3-18

2022-3-18