- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

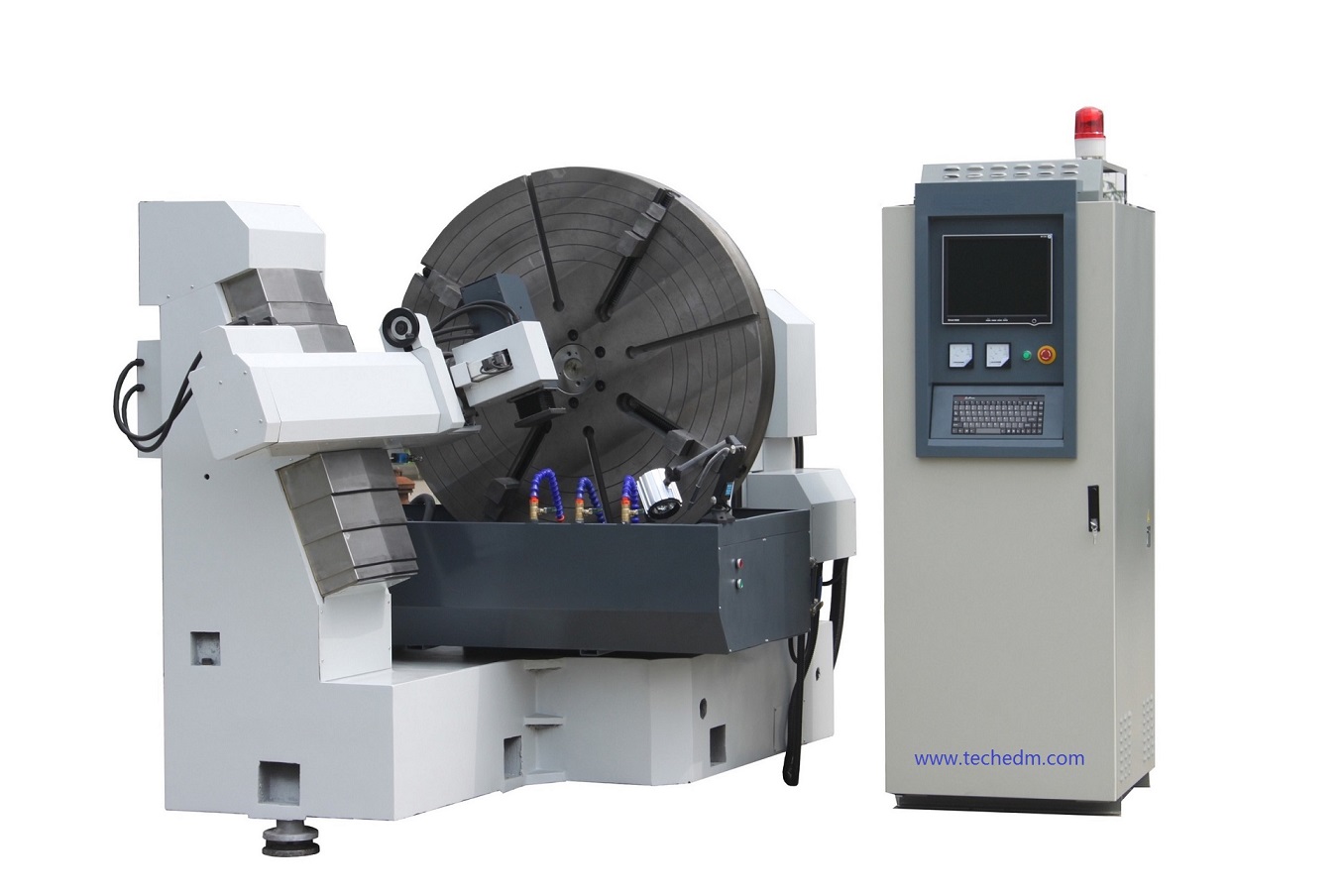

I. Main specification form:

|

Specification |

Model |

||

|

Parameters / Specification |

EDM430HCNC |

EDM540HCNC |

EDM850HCNC |

|

X*Y*Z Travel (mm) |

400*300*300 |

500*400*300 |

800*500*400 |

|

Working table size L*W (mm) |

700*400 |

900*500 |

1100*650 |

|

Principal axis load (Kg) |

120 |

150 |

200 |

|

Machine load (kg) |

1500 |

1800 |

3000 |

|

Distance between electrodeand working table (mm) |

320-620 |

390-690 |

500-900 |

|

Size of oil reservoir (mm) |

1130*710*450 |

1370*720*450 |

1800*1100*600 |

|

Machine weight (kg) |

1800 |

2500 |

4500 |

|

Machine size(mm) |

1650*1980*2300 |

1890*2210*2500 |

2500*2840*2700 |

|

Optimal surface (um) |

≤0.2 |

≤0.2 |

≤0.2 |

|

Mix electrode wear off(%) |

≤0.1 |

≤0.1 |

≤0.1 |

|

Position (mm) |

0.01 |

0.01 |

0.015 |

|

Repeat position(mm) |

0.006 |

0.006 |

0.01 |

|

Max machining speed (mm3/min) |

≧500 |

≧500 |

≧900 |

|

Max machining current (A) |

50 |

50 |

100 |

|

Motors(x/y/z) |

Panasonic AC servo motors |

||

II. Standard Equipment Functions

1. TFT LCD display, keyboard and mouse input

2. Three axis linkage motion, vast position memory

3. Database function: The different parameters are available for different electrodes and work pieces like Copper/steel, graphite/steel, graphite/aluminum, copper/brass etc.

4. Auto-machining function: Input the electrode and work piece material, machining area, electrode offset, final finish, and the parameters will be select from the database automatically.

5. Auto-positioning: surface finding, hole center pointing, any 3 points to find the center, edge-touching, etc.

6. Auto arc-cleaning: real-time checking the discharging gap during working, in case short or arc happens, the alarm works and arc-cleaning.

7. Oil level -control, oil temperature –control

8. Functions of memorizing when power was cut and auto-stop after processing

III. Standard Accessories

1. Machine body

2. Conctroler( including computer)

3. Water tank

4. Extinguisher

5. Working light

6. Tool box

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap