- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

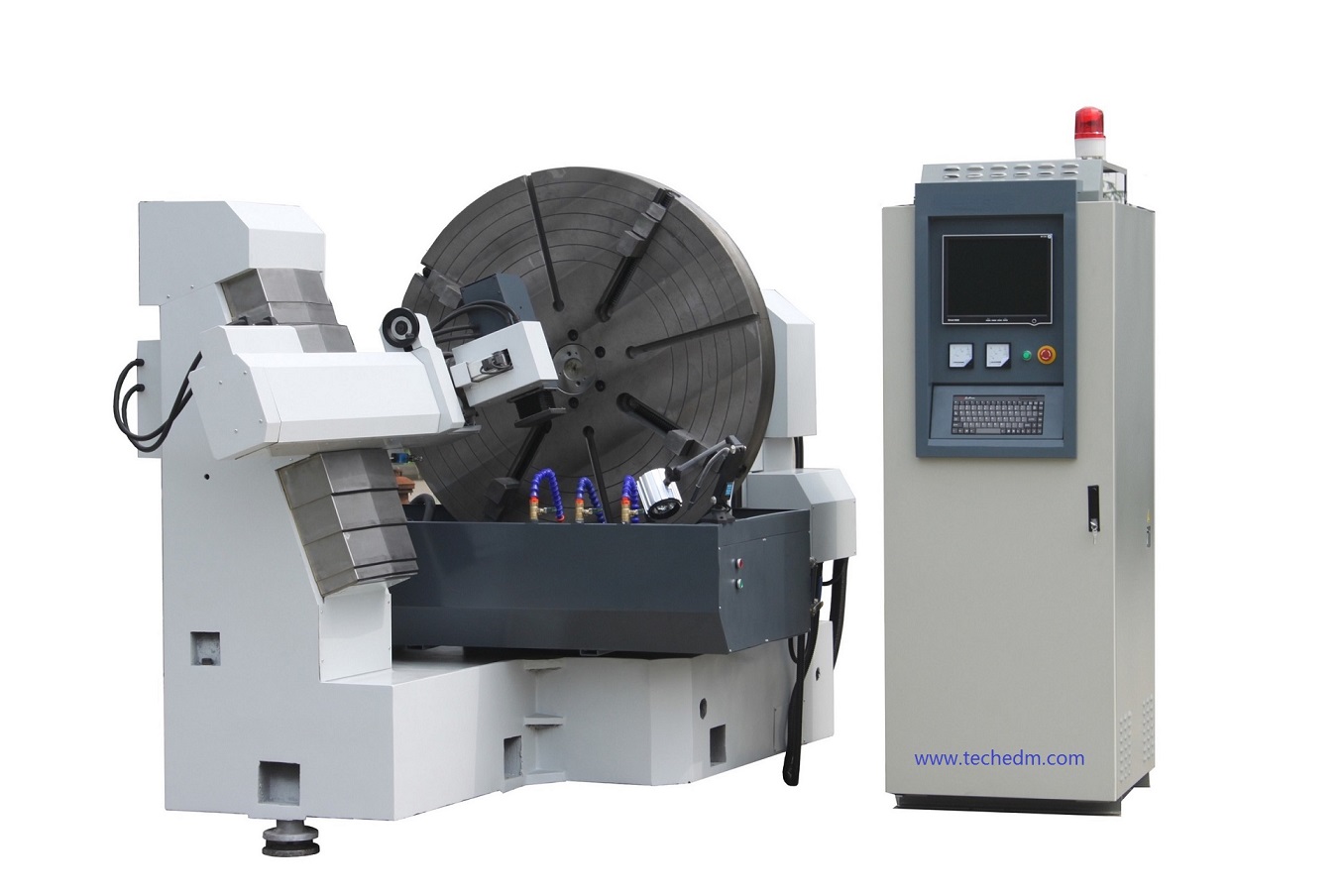

I). Main Specification

Model

TEDM 70CNC

TEDM100CNC

TEDM130CNC

TEDM180CNC

TEDM200CNC

Work

table(mm)

900x500

1200x600

1400x700

2000x1000

2500x1000

X

axis travel(mm)

700

1000

1300

1800

2000

Y

axis travel(mm)

400

500

600

700

700

Z

axis travel(mm)

300

400

500

500

500

Best Roughness(um)

0.2

0.2

0.2

0.2

0.2

Max

machining speed(mm³/min)

500

500

500

500

500

Max

electrode weight(KG)

50

80

100

200

200

Max

work piece weight(KG)

3000

4000

6000

10000

18000

Table

to electrode nose (mm)

500~800

500~900

550~1050

800~1300

800~1300

Power

Input(KVA)

13

13

13

13

13

Max

work piece dimension(mm)

1400x850x500

1800x1100x600

2200x1300x650

3500x1800x850

3500x1800x850

Tank

capacity(L)

860

1550

2400

2160

2160

Machine

net weight(KG)

4000

5000

8000

13000

15000

Machine

dimension(L*W*H)( mm)

2380X3060X2675

2770X3685X2775

3720X4200X3430

5000X4500X3650

5000X4500X3650

|

II) Standard Equipment Function a) CNC control system, networking support |

|

|

b) 15-inch LCD Touch Screen |

|

|

c) USB Input & Output |

|

|

d) AC Panasonic Servo Motor |

|

|

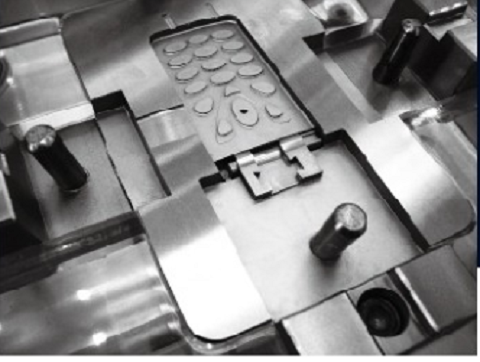

e) Clamping Chuck for job holding |

|

|

f) Electrode holder |

|

|

g) Working Light |

|

|

h) Auto Processing&Positioning |

|

|

i) Expertise Technology Database System |

|

|

j) Surface Finishing & Special Circuit for Finishing hard alloy |

|

|

k) Functions of memorizing when power was cut and auto-stop after processing |

|

|

l) Function of auto-adding transitional arc (Arbitrary angle) |

|

|

m) Data transmission |

|

|

III) Standard Accessories |

|

|

a) Machine sizing block |

1 set |

|

b) Manual control box |

1piece |

|

c) Explosion-proof fluorescent light |

1piece |

|

d) Filtration paper core |

4pcs |

|

e) Standard toolbox (Tools included) |

1piece |

|

f) Operation manual |

1piece |

|

g) Hand fire extinguishers |

1piece(dry type) |

|

IV) DOCUMENTS |

|

|

a) Two sets for technical literature |

|

|

b) Provision of machine parameters. |

|

|

c) Dedicated programmer in case of PLC installed. |

|

|

d) Machine program soft and hard copies. |

|

|

e) Manual for machine programming. |

|

|

f) Manual for calibration procedures. |

|

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap