- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

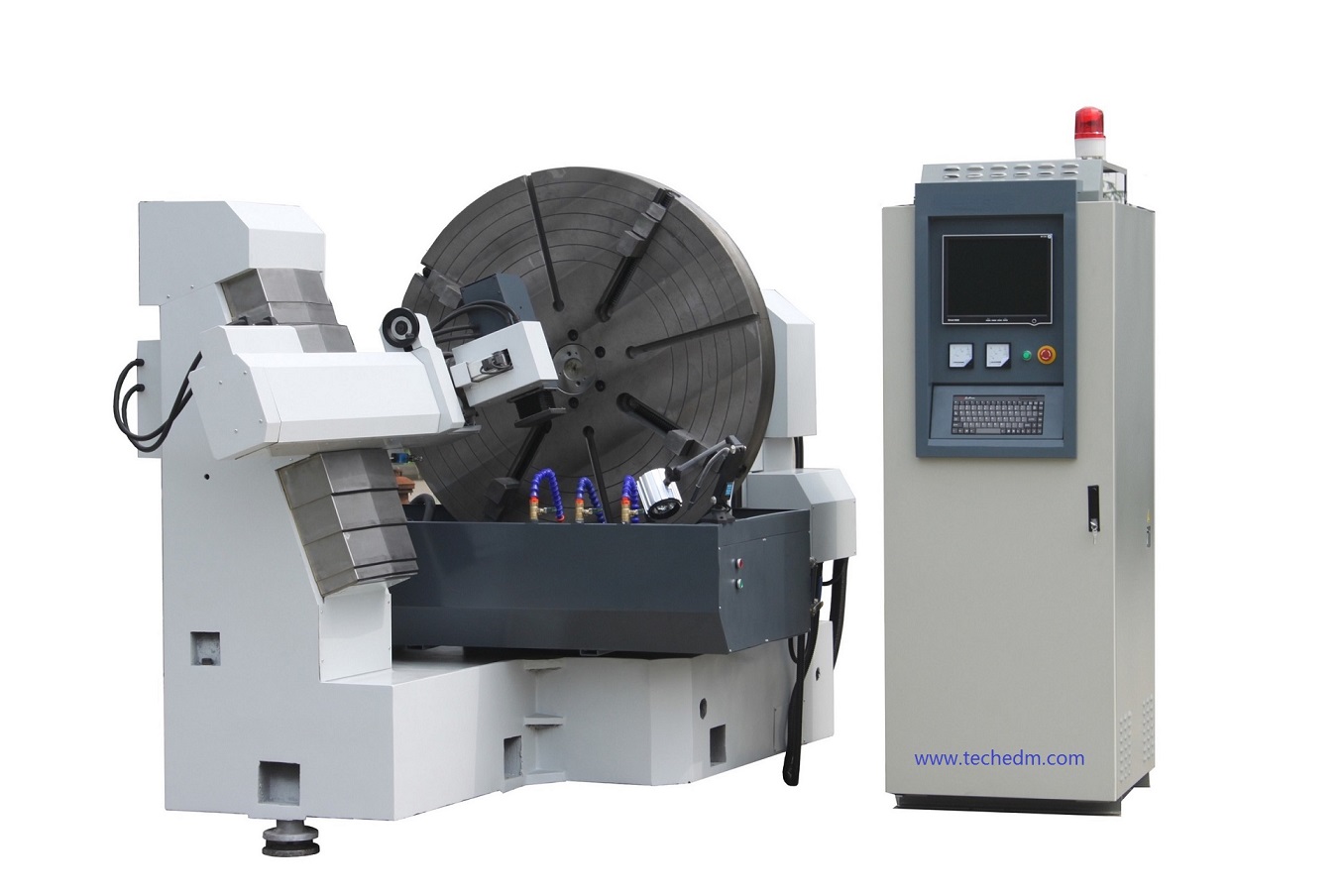

I). Main Specification

Model

TEDM30CNC

TEDM35CNC

TEDM45CNC

Work

table(mm)

600x400

600x400

600x400

X

axis travel(mm)

300

350

450

Y

axis travel(mm)

250

250

300

Z

axis travel(mm)

270

300

300

Best Roughness(um)

0.2

0.2

0.2

Max

electrode weight(KG)

25

50

50

Max

work piece weight(KG)

400

550

800

Table

to electrode nose (mm)

295-565

250-550

300-600

Power

Input(KVA)

13

13

13

Max

work piece dimension(mm)

950x620x360

950x620x400

1000x640x450

Tank

capacity(L)

470

470

520

Machine

net weight(KG)

2000

3000

3500

Machine

dimension(L*W*H)( mm)

1880x2630x2240

2100x2150x2215

2200x2150x2265

|

II) Standard Equipment Function a) CNC control system, networking support |

|

|

b) 15-inch LCD Touch Screen |

|

|

c) USB Input & Output |

|

|

d) AC Panasonic Servo Motor |

|

|

e) Clamping Chuck for job holding |

|

|

f) Electrode holder |

|

|

g) Working Light |

|

|

h) Auto Processing&Positioning |

|

|

i) Expertise Technology Database System |

|

|

j) Surface Finishing & Special Circuit for Finishing hard alloy |

|

|

k) Functions of memorizing when power was cut and auto-stop after processing |

|

|

l) Function of auto-adding transitional arc (Arbitrary angle) |

|

|

m) Data transmission |

|

|

III) Standard Accessories |

|

|

a) Machine sizing block |

1 set |

|

b) Manual control box |

1piece |

|

c) Explosion-proof fluorescent light |

1piece |

|

d) Filtration paper core |

4pcs |

|

e) Standard toolbox (Tools included) |

1piece |

|

f) Operation manual |

1piece |

|

g) Hand fire extinguishers |

1piece(dry type) |

|

IV) DOCUMENTS |

|

|

a) Two sets for technical literature |

|

|

b) Provision of machine parameters. |

|

|

c) Dedicated programmer in case of PLC installed. |

|

|

d) Machine program soft and hard copies. |

|

|

e) Manual for machine programming. |

|

|

f) Manual for calibration procedures. |

|

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap